How can I tell if a clamp is tightened properly?

After installing the clamp, immediately ensure if it has been installed correctly and is doing its job. A bad connection can harbor bacteria. Make sure that the clamp is neither over- nor under-tightened.

After installing the clamp, immediately ensure if it has been installed correctly and is doing its job. A bad connection can harbor bacteria. Make sure that the clamp is neither over- nor under-tightened.

Under-tightening the clamp = Leaves gaps between the ferrule and the gasket. Even if the connection doesn’t drip, the gaps may trap material where CIP processes can’t reach, thereby increasing the chances of bacterial accumulation.

Over-tightening the clamp = Over-compresses the gasket causing it to intrude into the pipeline. Any such intrusion will create a foothold for buildup and bacteria.

It’s important to ensure that the installation was successful. Check for the following:

Is the clamp over-or under-tightened?

Overtightening causes intrusion into the pipe

Under-tightening leaves gaps between the gasket and ferrules

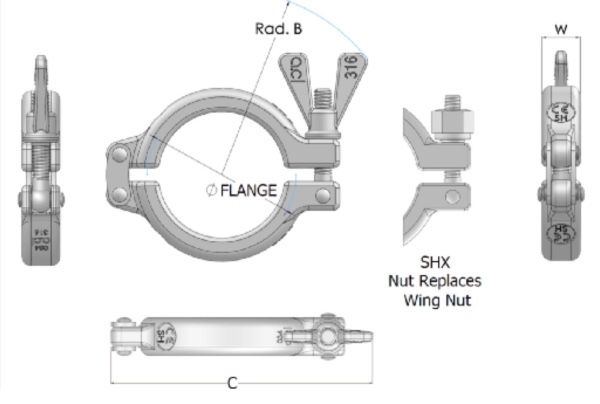

Jaws should not touch when properly-tightened.

Are the gasket and ferrules aligned?

In a proper installation, the gasket is slightly compressed and the bead is centered in the ferrule groove. The gasket’s inside diameter should be aligned with the pipe’s inside diameter so that there is no intrusion or void. The clamp jaws should never touch after tightening, or there may not be enough compression on the gasket to create a proper seal. This could be caused by a deformed or damaged clamp, overtightening, or using the wrong-sized clamp for the ferrule assembly.

Over-tightening can be spotted by checking for clamp jaws that touch. This should not occur because excessive pressure may cause the gasket to intrude into the pipe. Properly-tightened hygienic clamps instead have some space between the jaws.

Under-tightening results in too much space in between the jaws, which may leave gaps between the gasket and ferrules. This invites the opportunity for the ingress of pathogens or contaminants. Even if they do not leak these gaps can cause hard-to-clean areas to occur which clean-in-place processes cannot reach.